Recognizing the Ecological Benefits of Aluminum Factory Techniques

Light weight aluminum factory strategies play a crucial function ahead of time sustainability within the production industry. By implementing advanced recycling approaches and energy-efficient techniques, these strategies substantially lower waste and carbon impacts. Ingenious casting approaches even more improve source preservation initiatives. As markets significantly prioritize environmental responsibility, recognizing the full impact of these methods becomes important. What details improvements are leading the method in this makeover?

The Role of Light Weight Aluminum in Lasting Production

Lots of materials add to sustainable production, aluminum stands out due to its unique residential or commercial properties and recyclability. This light-weight metal is not only resilient but additionally has excellent rust resistance, making it an excellent choice for numerous applications, from automotive to construction. Its high strength-to-weight proportion leads to energy savings during transportation and usage. Moreover, light weight aluminum can be recycled forever without shedding its intrinsic high qualities, advertising a round economic situation.

The production process of light weight aluminum has advanced, integrating energy-efficient methods that lower carbon footprints. By making use of renewable resource resources, makers are significantly reducing the ecological impact linked with light weight aluminum manufacturing. Furthermore, the use of recycled aluminum requires significantly much less power contrasted to removing and refining key light weight aluminum, resulting in reduced greenhouse gas exhausts. As sectors seek lasting options, aluminum's versatility and eco-friendly attributes placement it as an essential product in the search of greener production techniques.

Advanced Recycling Techniques in Aluminum Foundries

Advanced reusing strategies in light weight aluminum foundries are revolutionizing the means scrap aluminum is refined and recycled. Innovative techniques, such as closed-loop recycling systems, make it possible for foundries to redeem light weight aluminum from manufacturing waste and out-of-date items successfully. These systems minimize material loss and enhance the high quality of recycled aluminum, making it a feasible choice to main aluminum manufacturing.

Furthermore, progressed arranging innovations, consisting of automated optical sorting and X-ray fluorescence, improve the splitting up of aluminum from various other materials, guaranteeing higher purity degrees in recycled outcomes. This accuracy minimizes contamination, which can endanger the stability of the last item.

The assimilation of innovative melting technologies, such as induction melting and energy-efficient furnaces, improves the reusing process, decreasing power consumption. Collectively, these technologies add to a much more lasting light weight aluminum market by lowering reliance on virgin products and lowering greenhouse gas emissions connected with aluminum production.

Energy Performance Improvements in Factory Operations

Power efficiency renovations in light weight aluminum foundry operations can significantly enhance sustainability techniques. Executing waste heat recuperation systems allows shops to repurpose excess power, reducing general power intake. Furthermore, improvements in process automation improve operations, resulting in reduced waste and optimized resource usage.

Waste Warmth Recuperation

Executing waste heat recovery systems in light weight aluminum factories substantially boosts power effectiveness by capturing and reusing excess thermal power generated during production procedures. These systems facilitate the conversion of thrown away warmth into usable energy, which can be used for various applications within the shop, such as powering or preheating materials devices. By recovering heat that would otherwise be gotten rid of into the setting, shops can considerably decrease their general power usage and greenhouse gas exhausts. This method not only reduces operational prices yet also promotes lasting techniques within the sector. Additionally, the adoption of waste warm recovery modern technologies lines up with regulatory standards intended at lowering ecological impact, making it an essential component of contemporary aluminum shop procedures.

Process Automation Advantages

Automating processes in light weight aluminum factories can significantly enhance power effectiveness by optimizing manufacturing process and minimizing waste. By applying advanced innovations such as robotics and machine learning, shops can enhance operations, minimizing unnecessary energy usage. Automated systems facilitate precise control over temperature and product handling, ensuring that energy is made use of only when required. In addition, real-time surveillance permits immediate changes, minimizing the threat of power loss. The combination of automation not only improves performance however additionally reduces operational costs, making foundries a lot more affordable. Consequently, these energy-efficient methods add substantially to sustainability goals, decreasing the environmental impact of light weight aluminum production while meeting boosting market needs - Precision aluminum casting. Boosted power performance with automation represents a crucial step in the direction of greener factory procedures

Reducing Waste With Cutting-edge Casting Approaches

Innovative spreading approaches play an essential duty in minimizing waste in light weight aluminum factories. Strategies such as innovative molding and the application of recyclable products significantly minimize production scrap. These practices not just improve effectiveness but also contribute to a more sustainable manufacturing process.

Advanced Molding Techniques

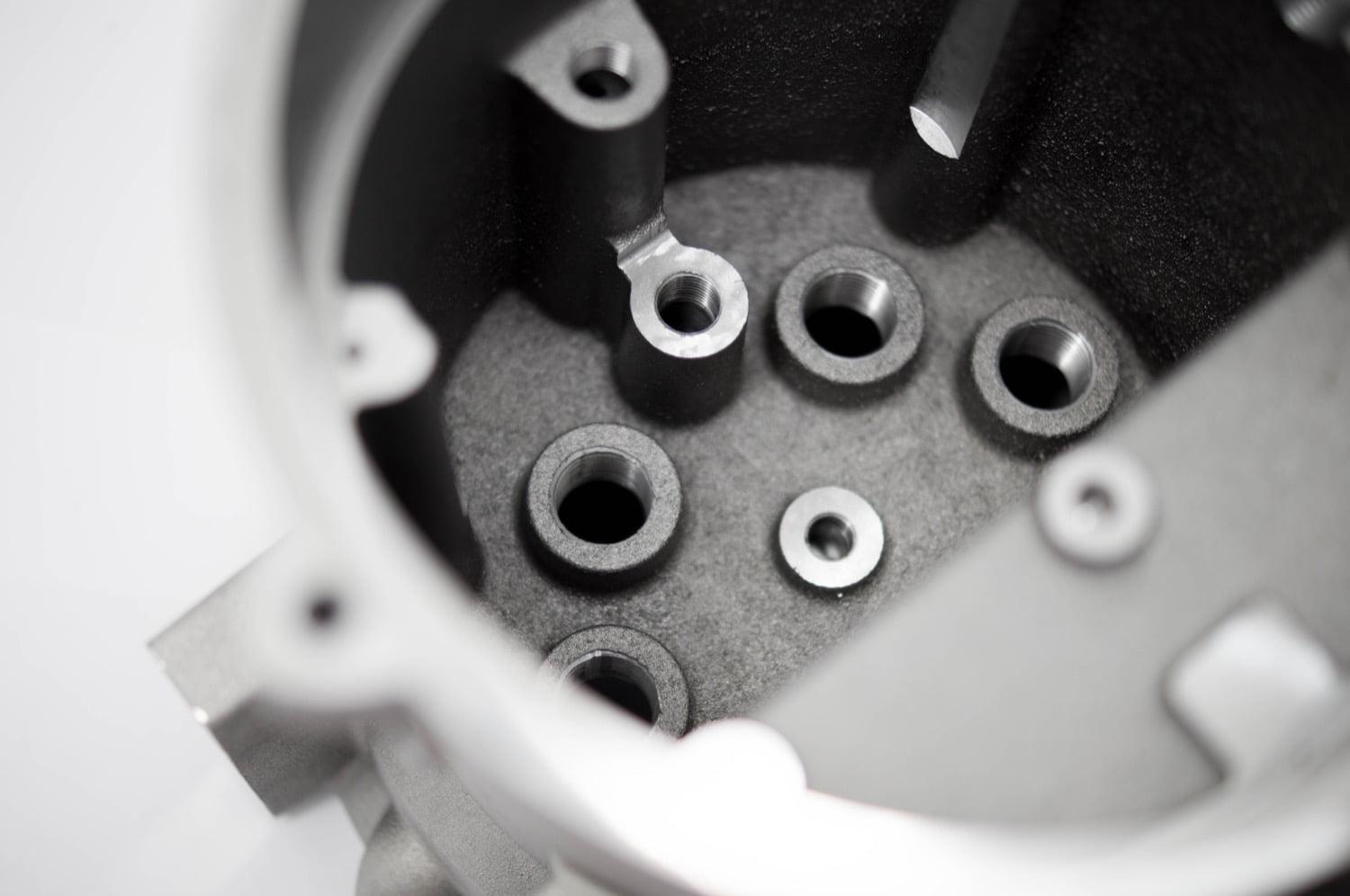

As industries progressively focus on sustainability, progressed molding strategies in aluminum factories become reliable solutions for lowering waste. These cutting-edge approaches, such as 3D printing and accuracy mold and mildew making, substantially enhance the efficiency of the spreading procedure. By making use of computer-aided style (CAD) and simulation innovations, makers can optimize mold geometry, lessening product usage while preserving product stability. In addition, progressed techniques allow the manufacturing of intricate forms that standard techniques can not accomplish, decreasing the requirement for additional machining and consequently decreasing scrap material. The adaptability of these methods enables for fast prototyping, additional decreasing preparations and energy his explanation usage. In general, the implementation of advanced molding techniques represents an essential step towards environmentally responsible aluminum production, straightening with worldwide sustainability goals.

Recyclable Material Application

Recyclable materials play a pivotal duty in reducing waste within aluminum shops, changing the spreading landscape through their reliable utilization. By including scrap light weight aluminum and various other recyclable parts into the manufacturing procedure, foundries can substantially decrease the need for virgin products. This not only saves natural deposits yet likewise decreases power usage connected with mining and refining. Ingenious spreading approaches, such as die casting and sand casting, permit smooth integration of these products, guaranteeing top notch results. Furthermore, using recyclable materials fosters a round economic situation, where resources are constantly reused and repurposed, decreasing garbage dump contributions. Eventually, the critical use recyclables boosts sustainability while advertising cost-effectiveness in light weight aluminum factory operations.

Decreasing Manufacturing Scrap

Life Process Evaluation of Light Weight Aluminum Products

Although aluminum is widely recognized for its long lasting and lightweight homes, a comprehensive Life process Analysis (LCA) reveals the ecological influences connected with its usage, manufacturing, and disposal. The LCA procedure analyzes the energy usage, greenhouse gas discharges, and resource deficiency connected to aluminum items from extraction of bauxite ore to end-of-life management. Primary light weight aluminum production is energy-intensive, commonly counting on fossil gas, which contributes substantially to carbon footprints. In contrast, recycling aluminum offers substantial ecological advantages, as it uses just a fraction of the power needed for primary manufacturing. Furthermore, the recycling procedure minimizes landfill waste and preserves natural deposits. The LCA likewise thinks about the product's long life and potential for reuse, stressing the relevance of lasting style. In general, comprehending the life process impacts of light weight aluminum items is important for making educated choices that focus on ecological sustainability within the market.

Case Studies: Effective Lasting Practices in the Market

The aluminum industry has begun to welcome cutting-edge lasting practices that resolve the ecological challenges identified in Life Cycle Analyses. One remarkable case is a leading foundry that executed a closed-loop recycling sites system, substantially reducing waste and energy consumption. By reusing scrap aluminum in production, the center attained a 40% decrease in its carbon impact.

An additional example involves a producer that adopted eco-friendly power resources, powering its procedures with solar and wind power - aluminum casting. This shift not just reduced greenhouse gas exhausts however also enhanced the company's credibility amongst environmentally mindful customers

In addition, a 3rd factory has purchased innovative spreading techniques, which optimize material use and lessen defects, even more lowering resource consumption. These instance research studies show that the aluminum market is qualified of integrating lasting methods, demonstrating both ecological responsibility and financial stability, eventually adding to a more sustainable future.

Often Asked Concerns

Exactly How Does Aluminum Contrast to Other Metals in Sustainability?

Aluminum is normally taken into consideration much more sustainable than many steels as a result of its recyclability, reduced energy needs for manufacturing, and reduced ecological influence. Its lifecycle efficiency exceeds that of steel and copper in various applications.

What Is the Carbon Impact of Light Weight Aluminum Shop Processes?

The carbon footprint of aluminum foundry processes varies, commonly ranging from 4 to 15 metric lots of carbon dioxide per load of light weight aluminum created. Factors affecting this consist of power sources, modern technology, and the efficiency of procedures.

Exist Health Dangers Related To Light Weight Aluminum Factory Procedures?

What Are the Costs Related To Lasting Aluminum Techniques?

The expenses linked with sustainable light weight aluminum techniques consist of greater first investments in modern technology, potential boosts in functional expenditures, and ongoing upkeep. These are commonly balanced out by long-lasting financial savings and minimized ecological influence.

Just How Does Light Weight Aluminum Recycling Influence Local Communities?

Light weight aluminum recycling positively influences regional neighborhoods by developing work, lowering garbage dump waste, and reducing energy expenses. It fosters financial growth and promotes ecological stewardship, causing healthier living conditions and improved area engagement in sustainability campaigns.

Additionally, the usage of recycled aluminum needs substantially less power contrasted to removing and improving key aluminum, leading to reduced greenhouse gas exhausts. Advanced recycling strategies in aluminum shops are reinventing the means scrap light weight aluminum is refined and recycled. aluminum casting. Implementing waste warm recuperation systems in aluminum factories considerably improves energy effectiveness by catching and reusing excess thermal power generated during production processes. Automating procedures in light weight aluminum factories can greatly enhance energy performance by enhancing manufacturing operations and decreasing waste. The carbon footprint of light weight aluminum factory procedures varies, commonly varying from 4 to 15 statistics tons of Carbon dioxide per bunch of light weight aluminum created